Project Description

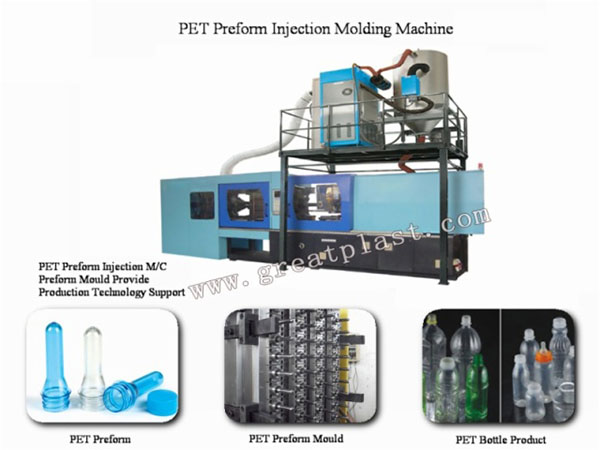

PET Preform Injection Molding Machine

Standard Features:

With deep experience and in accordance with PET preform characteristics, we have improve a lot to be fit for PET preform production

1.Professional PET screw and barrel with L/D 1:23 have higher mixing and plasticizing abilities. High torque screw driving system ensures screw’s injection speed

2.Big channels for cooling water regulating meet requirements for mold cooling.

3.Large eject force ensures multi cavity PET performs to be taken out efficiently.

| Unit | D250-PET | |||

| ITEMS | PET Special Injection rigid screw | |||

| INECTION UNIT | Screw Diameter | mm | 55 | |

| Screw L/D Ratio | L/D | 24.0 | ||

| Injection Weight | g | 640 | ||

| Injection Pressure | MPa | 185.1 | ||

| Injection Rate into Air | cm3/s | 236.3 | 271.0 | |

| Injection Stroke | mm | 253 | ||

| Injection Speed | cm/s | 9.5/11.6 | ||

| Screw Speed | rpm | 189 /232 | ||

| CLAMPING UNIT | Clamping Force | KN | 2500 | |

| Clamping Stroke | mm | 550 | ||

| Space Between Tie Bar | mm | 580*580 | ||

| Max. Mold Height | mm | 600 | ||

| Min. Mold Height | mm | 250 | ||

| Eject Stroke | mm | 160 | ||

| Eject Force | KN | 67 | ||

| No. Of Ejector Pins | piece | 9 | ||

| OTHERS | Max. Pump Pressure | MPa | 17.5 | |

| Pump Motor Power | KW | 22.0 | ||

| Heater Power | KW | 17.1 | ||

| Hopper Capacity | Kg | 50 | ||

| Oil Tank Capacity | L | 550 | ||

| Weight | T | 8.2 | ||

Standard Features:

With deep experience and in accordance with PET preform characteristics, we have improve a lot to be fit for PET preform production

1.Professional PET screw and barrel with L/D 1:23 have higher mixing and plasticizing abilities. High torque screw driving system ensures screw’s injection speed

2.Big channels for cooling water regulating meet requirements for mold cooling.

3.Large eject force ensures multi cavity PET performs to be taken out efficiently.

4.PID controlled barrel with exact temperature

5.We supply all PET preform and bottle production “Turn-Key” solution