Project Description

Blow molding machine 160L

Three tie bar mold-closing unit, three cylinders for clamping, make the clamping equally distributed and more steady.

Adopt the liner motion guide to the machine, reduce the friction force, make the motion quicker and increase the precision of the mold closing

Introduce “quick-charge”and energy saving valve to the hydraulic system, effective reduce to be the lower working temperature, extend the working life of the hydraulic parts, and save 20% to 40% energy power than the normal type.

Main Parameters | Unit | GRT160-160L |

Max. Product Volume | (L) | 160 |

Dry Cycle | (pcs/h) | 300 |

Screw Diameter | (mm) | 120 |

Screw L/D Ratio | (L/D) | 28 |

Screw Drive Power | (KW) | 75/90 |

Screw heating Power | (4ΦKW) | 30 |

Screw Heating Zone | (Zone) | 5 |

HPDE Output | (kg/h) | 250 |

Oil Pump Power | (KW) | 45 |

Clamping Force | (KN) | 800 |

Mold Stroke | (mm) | 600-1500 |

Mold platen size | (W×H)(mm) | 1250×1600 |

Max. Mold Size | (W×H)(mm) | 1000×1500 |

Accumulator Capacity | (L) | 18 |

Max. Die Diameter | (mm) | 520 |

Die Heating Power | (4ΦKW) | 25 |

NO. of Heating Zone | (Zone) | 5 |

Blowing Pressure | (MPa) | 0.8 |

Air Consumption | (M3/min) | 1.6 |

Cooling Water Pressure | (MPa) | 0.3 |

Water Consumption | (L/min) | 180 |

Machine Size | (L×W×H)(m) | 5.85×2.7×4.6 |

Machine Weight | (Ton) | 22.5 |

Automatic energy saving blow molding machine characters:

Three tie bar mold-closing unit, three cylinders for clamping, make the clamping equally distributed and more steady.

Adopt the liner motion guide to the machine, reduce the friction force, make the motion quicker and increase the precision of the mold closing

Introduce “quick-charge”and energy saving valve to the hydraulic system, effective reduce to be the lower working temperature, extend the working life of the hydraulic parts, and save 20% to 40% energy power than the normal type.

Variety of function used for different product technological requirements: bottom blow and lift, rotation, encapsulation, sub-mould, robot. Parison control system, etc…

Basic equipment

Clamping system: fixed “linear guide ” clamping structure to ensure mold-lock uniform, knit line smoother

Extrusion system: hard gear box + import inverter

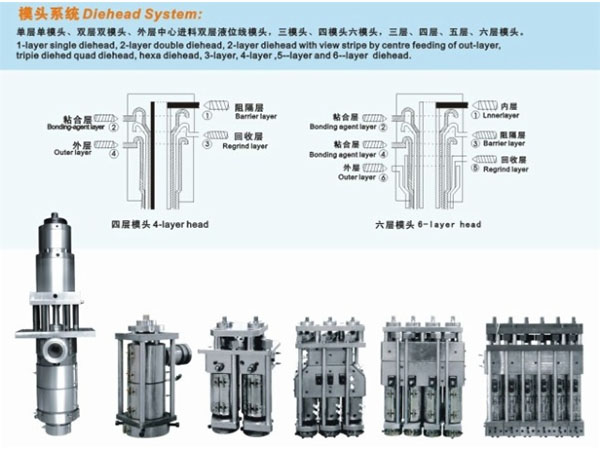

Die system: accumulator die head

Hydraulic system: Famous valve, seal parts and energy saving proportional hydraulic valve integration

Control system: Import PLC+touch screen, making the operation easy. PLC automatic temperature control model ,automatic malfunction Self-diagnosis alarm