Project Description

Double station blow molding machine 2L-5L

BASIC EQUIPMENT

Clamping system Single station +High-precision guide+Large arm cylinder axle

Extrusion system Hard gear box+ inverter

Die system Control-incoming die with special steel

Hydraulic system Hydraulic valve, seal parts and proportional control

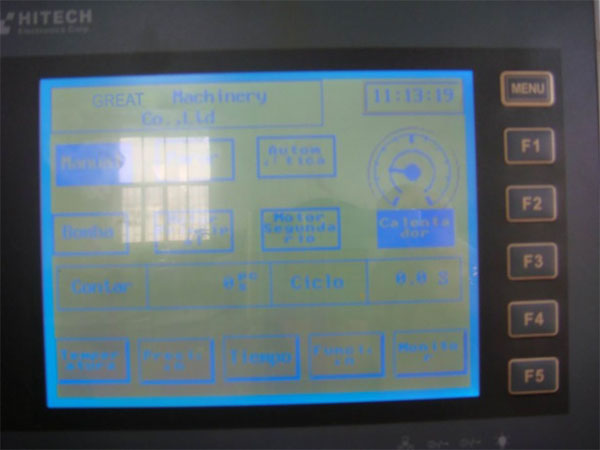

Control system Import PLC+Human-machine+PLC automatic temperature control model

|

Main Parameters |

Unit |

GRT70-5L |

|

Max. Product Volume |

(L) |

5 |

|

Dry Cycle |

(pcs/h) |

700×2 |

|

Screw Diameter |

(mm) |

70 |

|

Screw L/D Ratio |

(L/D) |

24 |

|

Screw Drive Power |

(KW) |

22 |

|

Screw heating Power |

(3ΦW) |

7.2 |

|

Screw Heating Zone |

(Zone) |

3 |

|

HPDE Output |

(kg/h) |

90 |

|

Oil Pump Power |

(KW) |

7.5 |

|

Clamping Force |

(KN) |

65 |

|

Mold Stroke |

(mm) |

148-508 |

|

Max. Mold Size |

(W×H)(mm) |

380×390 |

|

Max. Die Diameter |

(mm) |

145 |

|

Die Heating Power |

(4ΦKW) |

2.5 |

|

NO. of Heating Zone |

(Zone) |

3 |

|

Blowing Pressure |

(MPa) |

0.6 |

|

Air Consumption |

(M3/min) |

0.6 |

|

Cooling Water Pressure |

(MPa) |

0.3 |

|

Water Consumption |

(L/min) |

60 |

|

Machine Size |

(L×W×H)(m) |

2.9×2.1×2.7 |

|

Machine Weight |

(Ton) |

7.8 |